99%

Control up to 99% inventory accuracy when scanning barcodes.

60%

Save 60% time on loading, unloading and tallying.

99%

Paperless warehouse, automation and integration on a single platform.

Comprehensive warehouse management solution for shippers / 3PL

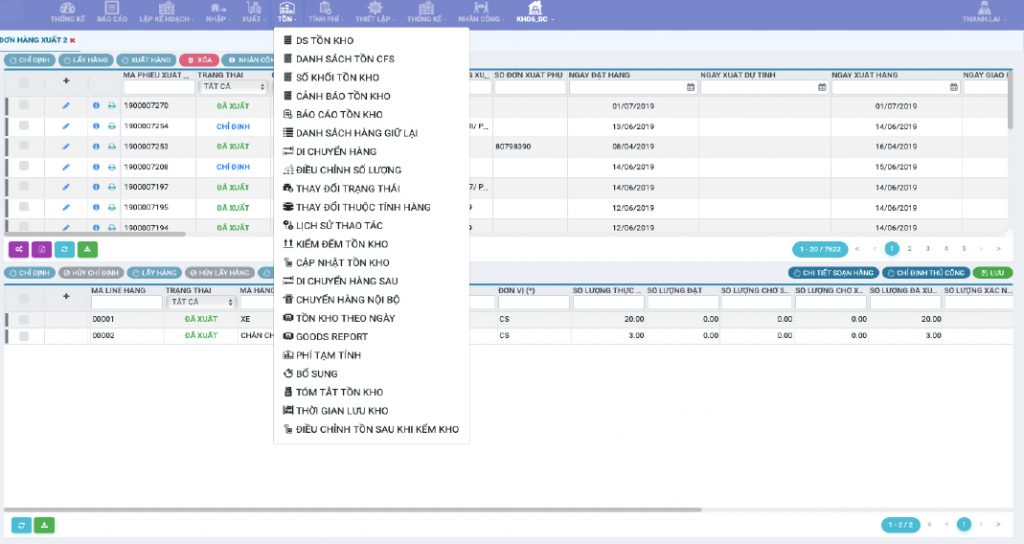

SWM (Smartlog Warehouse Management System) applies an intelligent algorithm to optimize the operation process of the warehouse & distribution center to help monitor, operate more easily, and minimize errors.

SWM warehouse management solution is an ideal choice for logistics companies, the system has been and is being used for FMCG, F&B, pharmaceutical, chemicals, electronics, Garment,…

Replace error-prone and ineffective manual operation!

The system is automatically updated and operated with a visual chart.

Diversify tactics to meet the specific requirements of each type of warehouse.

Real-time warehouse monitoring

Real-time recording status, minimized manual action.

Easy operation anytime, anywhere on web platform, multi-language app.

Allows creating own data fields, customized according to customer needs.

Integrated dock management function, human resource productivity.

Automatically export reports on demand, schedule inventory, inventory.

The system easily integrates with other software and hardware.

Compose and export goods by accurate handheld, save time and cost.

Check information, goods status.

Moving inventory directly by handheld.

Comprehensive control of all transactions with user names and dates of execution.

Management of the entire status of goods: Good goods, damaged goods, goods awaiting processing…

Trace the history of operations, exports, imports, and inventory adjustments…

By location, LOT: independent, even, odd, damaged or expired goods.

By LOT number: By controlling the LOT number, the warehouse keeper can easily identify goods that have expired or are nearing expiration.

By Pallet ID, Carton ID, LPN anywhere.

Tally Inventory based on location and area.

Proactively control with handheld devices.

Save time and paperwork costs.

Helping businesses to manage their warehouse more easily, intelligently and efficiently

» Receving

» Tally

» Put Away

» Inventory

» Loading

» Sorting

» Replenishment

» Picking

» Consolidating

» Checking

» Cross Docking

» RF/Mobile

» Moving

» VAS

» Line flow

» Vendors Manage

» Dock Scheduling

» BI

» TMS, ERP Intergarated

» Visual reporting

» Automatic invoice

Set up tactics to arrange goods by region, characteristics of goods, size, speed of goods movement, speed of inventory rotation, …

Precisely designating each location for putting away and automatically allocating goods. Optimizing the location and route for users.

Peripheral device matching, recording user actions in real time.

Set up the strategy of getting goods according to FIFO, shelf-life, date of manufacture, expiration date, Batch, Lot, BOM, Kit …

Set up a strategy for picking orders, groups, regions, and wave picking.

Operational efficiency analysis and operational integration reporting.

Directly and online monitoring of warehouse operating efficiency

Report output, import, inventory and other status of orders

Export to Excel, PDF and printer according to common standards

Control the amount of increase or decrease in stock, capacity and warnings about: capacity, warnings about excess inventory, too high or too low, about expired or expired items, …

Customize automatic alerts on demand: Import, export wrong SKU, Order at wrong location, Actual receipt is different from plan,…

Ability to monitor inventory, and customize according to customer needs (shelf-life, A-Z, product lifecycle, 3D surveillance …)

Minimize inventory costs: operating costs, shipping costs of inventory, and increase efficiency of picking and packaging operations.

Users access the inventory list on the website anywhere and at any time on a computer with an Internet connection.

The feature allows adding and adjusting reports according to customer needs with excel files for each end-user function.

End-user is decentralized according to each level of management, customized reports, excel data export forms according to each customer’s needs, each warehouse according to each end-user.

Designed in accordance with the business operations of the business, the operating model.

Displaying inventory right on the order, SWM warehouse management app helps you know if the item meets the requirements of the order.The quantity of goods will be automatically adjusted to increase and decrease corresponding to each time. stock entry, sales or inventory. Supports all real-time operation steps, SMM flexibly processes orders with a wide range of features: Scan barcodes by camera, search information by voice, Bluetooth connection with receipt printer, …

Support to manage many customers, many warehouses in the same system.

Flexible reconciliation, transaction, and export / import planning functions.

Easily grasp best-selling goods and inventory so that there are plans to replenish goods, discharge goods, and promote.

Manage typical goods, assembled in parts (BOM, Kitting,). Automatic Hold & batch output management (SPLIT).

Additional materials and accessories at the production line. Tool for tuning production orders in real-time. (Just in time)

Comprehensive tracking and management of quantity, size, color, and material properties. Supports flexible variable measurement units.

Manage packing, recording, labeling and managing garment quality. Strictly manage the input material inspection process.

F&B

Manage the expiry and expiry status. Automatic location selection based on the temperature of the goods.

Management of labor and finance is based on many factors: suppliers, customers,…

Easily track & trace goods flow from start to finish by serial.

Manage scanning information on RF, QR, Barcode, … standardize the verification and collation process for consignments and invoices.

Flexible conversion calculator & support accurate costing method.

Easily make periodic inventory check sheets, accurately capture the quantity of each drug in stock, quickly balance inventory.

Fill in the registration form below, Smartlog will contact you soon.